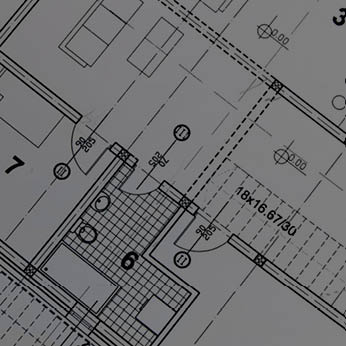

Cold rolled components combine with fabricated HRS sections and are assembled in-house into storey height panels, typically 3m to 8m in size. External panels receive an A1 fire-rated 12mm Y-wall sheathing board to provide water and fire protection. Depending on client requirements, additional insultation and support channels are installed at this time. Each panel receives a unique panel assembly number ready for its timed slot in the on-site install process.

380,000m2 panel capacity annually

Based in our 100,000sqft manufacturing facility the assembly line and team can assemble a staggering 380,000m2 of Sigmat LGSF panels.

18,200 panels assembled annually

13 in-house assembly team working to precise and stringent factory conditions, giving guaranteed delivery to site timescales. Pre-site tested to deliver accurate and quality panels on site.

Standard and Complex Volumetric Panels

External panels manufactured to include pre-formed door and window openings. Window and door openings can be glazed offsite further reducing overall build programme timings. The external face can be sheathed with a silicone particle board and where required foil-faced insulation and stainless steel brick tie channels.

Unique In-house assembly line

Our unique in-house assembly team assemble the panels using Sigmat patented components for superior strength panels, ready to be loaded onto trailers and delivered to site.

In-House Panel Assembly

Panel assembly hub

In-house team on the panel assembly line

Standard or complex volumetric panels assembled on the line

Assembled panels ready for delivery to site