Concern for the environment and promoting a broader sustainability agenda are integral to our core values.

We are committed to creating and maintaining good sustainable practises which reduce environmental impact to our activities and of each project.

The sustainability of our products, the welfare of our team and how we support the communities we work within, are all central to our ethos. As a company, we will continue to invest in R&D to create industry leading, sustainable products by embracing renewable and recyclable resources and materials. By making mindful procurement choices and working with organisations who share our vision, we will promote a joined-up approach to sustainable best practice.

Preparing For A Bright, Greener Future

With a strong focus on innovation, our overriding aim is to reduce the impact our business has the environment by providing effective, goal focussed solutions for our clients, protecting our team and safeguarding the communities we work in.

Our sustainability agenda focusses on three key areas:

Building The Best

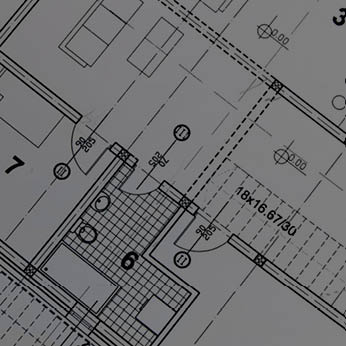

LGSF technology, is, by its very nature, one of the most sustainable construction methods on the planet. By harnessing the power of recyclable steel combined with world class design, we build forever structures that have minimum impact on the environment.

Protecting The Planet

All of our structures are built using 42% recycled materials and as steel is one of the world’s most re-usable materials (with impressive 90%+ recovery credentials) our building process is one of the most sustainable in the industry. Less materials also means reduced transportation requirements and the pre-fabricated nature of our designs means we can ensure site waste is virtually eliminated. Finally, with a 30% faster build speed and less operatives on site, LGSF offers safe, socially distanced site options for MMC in the post-pandemic world.

Creating Communities

By working with innovative main contractors, talented architects and world-class designers we create low-impact structures that work for modern life. From education to leisure and residential to commercial, our projects all aim to enhance the built environment and create sustainable communities.

Company Environmental Initiatives

Recycling & Waste

No waste sent to landfill.

97% of our manufacturing waste is recycled, and 3% which cannot be recycled is turned into electric energy and fed back into the grid.

Electric Vehicles

We are committed to having all our fleet on hybrid or full electric by 2025.

In our factory, we are replacing our fleet of gas powered pallet handlers with electric vehicles.

Car Sharing

Car sharing is encouraged where possible to save on unnecessary journeys.

Cycle to Work Scheme

We're pleased to offer many benefits to our employees including a cycle to work scheme.

Solar Panels

We are committed to installing solar panels on our factory and warehouses over the next 5 years.

Low Energy Lighting

Low energy LED units have replaced all internal fluorescent factory light units and the floodlights in the yard. These are linked to ambient daylight sensors so the lights are only on when required.

Sustainability of LGSF Structures

Recycled Content

Sigmat structures are built using steel with 42% recycled content.

Reduced Carbon Emissions

Substantial reduction in the overall carbon footprint of a building.

Remember manufacture of concrete generates 9% of the world's carbon emissions - almost 3 times as much as the entire aviation industry.

Lightweight

Light gauge framed steel structures are substantially lighter than traditional steel framed buildings allowing significant reduction in the construction of foundations.

End of Life Recyclability

It is well known that steel is one of the world’s most recycled materials with a potential recovery and re-use factor in excess of 90%.

Construction Site Waste

Site waste is virtually eliminated using pre-engineered and fabricated product so contributes to zero waste targets on site.

Reduced Transport

As the volume of material on our delivery is greater there are less vehicle deliveries to the project, which assist in reducing the impact on the environment.

Speed of Construction

Speed of construction increased by over 30% and less operatives enable social distancing which reduces site impacts - improves site safety due to less operatives.

Specifications

Floor concrete specification: C32/40

Steel specification: BS EN 10346

Galvanising specification: S450GD+Z275