Our state-of-the-art manufacturing facility is located on the outskirts of Leeds. Our 100,000sqft factory is home to our cutting-edge roll-forming mills and panel assembly zone.

Roll forming

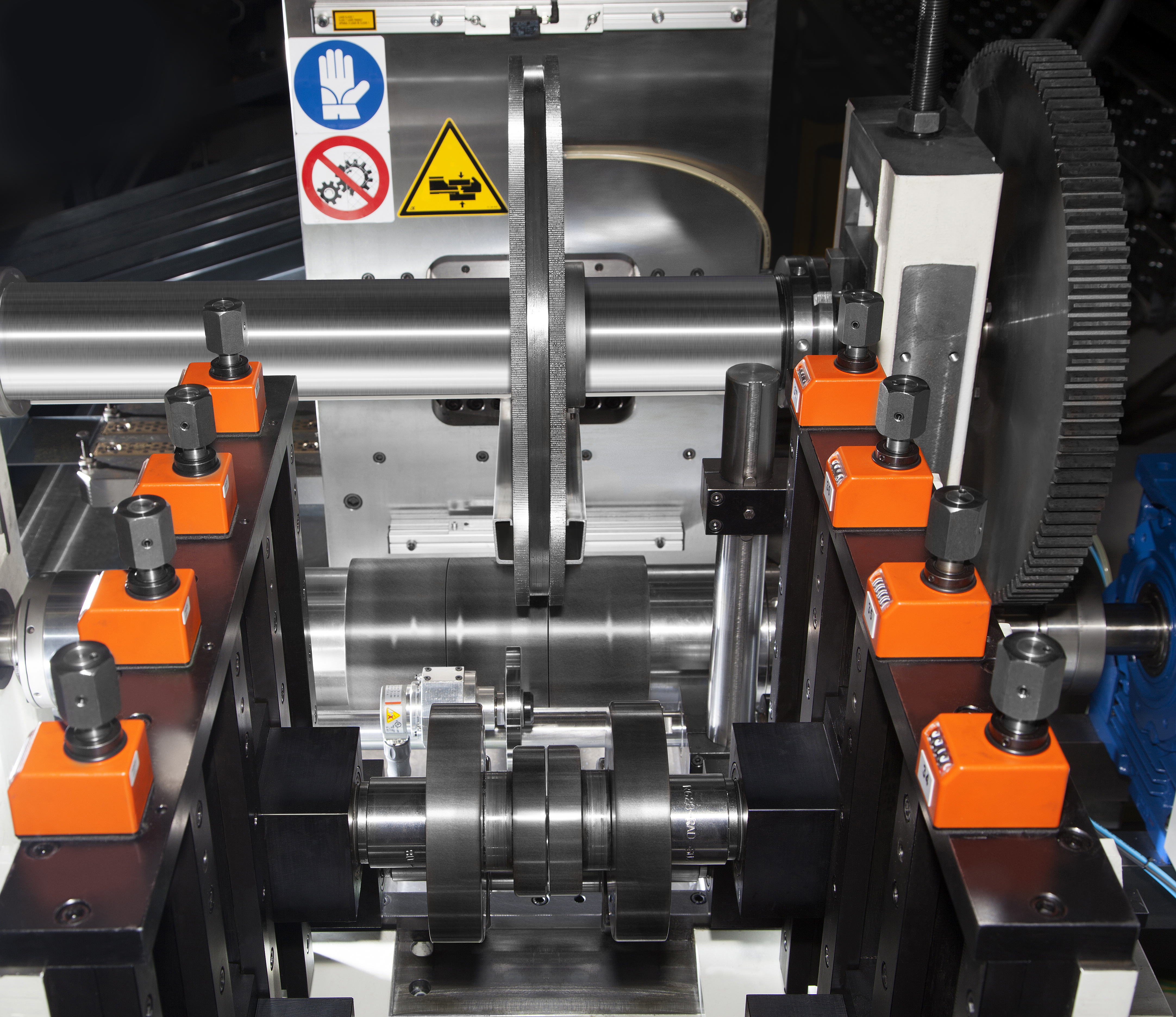

Our roll forming mills manufacture our patented range of Light Gauge Steel Framing Systems. The mill is fitted with fully automated data control systems to receive the numerical manufacturing data direct from our 3D CAD modelling software in pre-determined phases. A unique reference mark is clearly printed on each piece we produce.

It allows the manufacture of our steel profiles to significantly better tolerances than were previously available in the industry. The tight corner radii ensure we achieve full contact end bearing for our studs, which are manufactured to exact lengths and piercing tolerances.

At the end of the mill, an out feed transfer table allows individual elements to be manufactured directly into panel assembly bundles, ready stacked on automated racks for transfer to the assembly area.

All SIGMAT components are roll-formed in our factory from galvanised steel coils which are pre-slit to the required profile girth. All Sigmat profile sections are manufactured using hot dipped galvanised steel to (BSEN 10143:2006) in grades from S280 and S450, as required. They have a Z275 coating and are supplied self-finished.

Hot Rolled Manufacturing

We manufacture a variety of hot rolled steel elements, including steel stairs and balcony steel work. These are shot blasted to Sa2.5 standard and coated with primer paint or a hot dip galvanised finish where required.

When feasible, integral posts and lintels are included in our off-site panel assembly process. Beams and other major elements will be delivered to site with the wall panels for fitting on-site.

When a podium structure is required we offer a fully integrated design and construct package with beams positioned under all load bearing walls.

We maintain strict in-house quality control and co-ordinate the fabrication of light gauge and hot rolled elements to ensure that everything delivered to site is compatible and simple to install.

Scale and speed of supply

We provide a seamless process from plan and assembly drawings to site-ready panels. Our offsite capacity enables multiple components and frames to be manufactured and assembled simultaneously. This efficiency is aided by our in-house logistics services which plan ahead for delivery and on-site installation.

Collation of Kit of Components

Following profile manufacture into individual panel bundles, the profiles and hot rolled elements are transferred to the assembly bays. They are then pre-assembled in jigs in our factory to form storey-height panels up to 7.5m in length.

All internal and external wall panels are assembled in a vertical orientation in jigs (including boarding/insulation to the external panels as required). These are placed on rolling conveyor lines, eliminating the need to handle the panels until they are complete and quality checked. At this point they are loaded on to our transport for delivery to site.

All panels are assembled using our unique recess boss and bolt system in close tolerance holes with locking nuts. Panels are assembled in accordance with the panel assembly drawings and are individually stamped with a unique bar code to allow tracking through the entire process, including installation on site.

All sheathing and insulation boards are pre-cut to a material list schedule provided from the 3-D CAD model. When hot rolled steel elements are required in the panel they are pre-fabricated for inclusion into the panel assembly process.

Our continuous improvements also include:

- a full range of pre-fabricated steel stair systems (manufactured in house)

- unique folded plate section profiles for stair trimmers, corridor bridging beams, canopies and lintel beams etc

- an edge protection system which removes the need for free-standing scaffold allowing follow-on work to proceed quickly

Complex Volumetric Panels

External panels are manufactured to include pre-formed door and window openings.

The external face can be sheathed with a silicone particle board and where required foil-faced insulation and stainless steel brick tie channels. This helps to provide a dry envelope construction allowing rapid commencement of internal trades.

Window and door openings can be glazed offsite further reducing overall build programme timings.

The unique Sigmat load bearing stud profiles use a double lip configuration, which together with a web stiffener rib, significantly increases the axial load capacity over that of a similar traditional 'C' section of a similar weight per metre.

Our unique single-piece ‘Top Hat’ Wall Head member has removed the need for a 2 or 3 member solution. It reduces component manufacture, panel assembly and on-site installation time. In addition, it provides improved temporary weathering during construction, allowing the earlier introduction of follow on trades.